-

WhatsAPP: +86 137 1365 3495

-

WeChat: +86 137 1365 3495

-

E-mail: info@ace-mold.com

Export mold with high mold life time

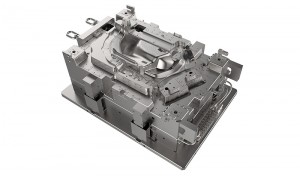

Ace has 20 years’ experience of mold and injection molding export services. In the past 20 years, we have improved our mold product design techniques and optimized our production processing. At present, we have set up a very reliable production and processing system,we provide the best plastic mold and plastic injection molding service for our clients.

From quotation to mold shipping, every production stage is all carefully planned. Ace holds an internal meeting with tool design team, raw material purchasing and processing department to provide our client with the plastic tooling and plastic part injection unit price. Our customers would also provide the necessary information such as injection machine data, resin data sheet and mold standard requirements.

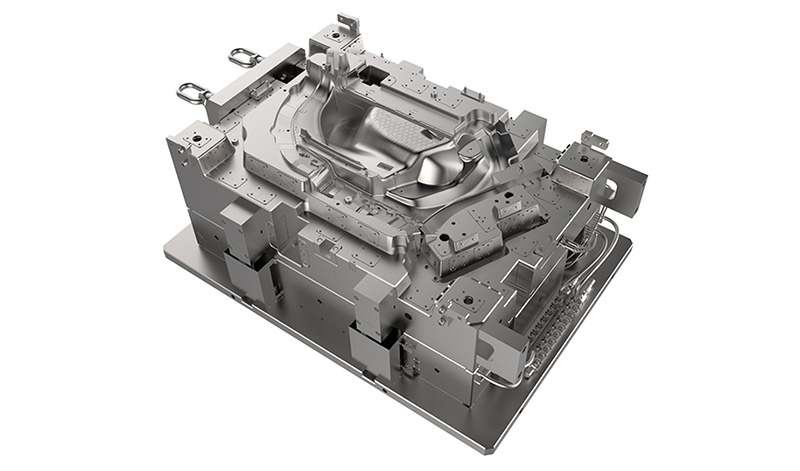

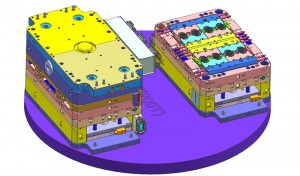

Ace is very focuses on the plastic mold and plastic part precision request. With our best CNC machine we will make the plastic mold tolerance reach +-0.008mm, for some high precision medical plastic mold and high cavity plastic mold, we can use our Japan Yashida machine, for which the tolerance could reach +-0.002mm, and the part tolerance can be +-0.009mm. We have produces numerous projects for medical parts used for the injection medical syringe and syringe plungers, blood collecting vessel part with 128 cavities and mold tolerance request o be +-0.005mm.

We also provide high precision components, such as high precision mold sliders and high precision mold cavity block and mold core blocks. We are able to do 100% as customer’s drawing requirements.

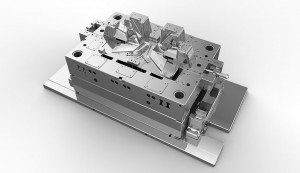

At Ace, we have a team for New energy vehicle plastic mold and parts design and manufacture.

We successfully built 80 tools per year for our overseas client for the new energy automotive product, with fast delivery time and also high precision request.

Ace also imports Tertiary measuring instrument, from the plastic mold components until the plastic parts sample we provide to our client difference in speciation report make sure all the dimensions will comply with customer request.

What is your production lead time?

Our standard lead time for mold production is 4 weeks or depending on the complexity of the part. For plastic molded parts is 15-20 days depending on your quantity requirements.

What is your payment term?

50% as payment deposit, 50% balance will be paid before shipping. For small amount, we accept Paypal, Paypal commission will be added to the order. For big amount, T/T is preferred.

How do you deliver the goods?

We have our own logistics department that could provide shipping costs via Sea or Air freight, Incoterms EXW, FOB, DDP, DDU etc. Or we can work with your appointed shipping forwarder.

How can I guarantee our quality?

During mold making, we do material and part inspection. During part production, we do 100% full quality inspection before packaging and reject every parts that is not according to our quality standard or the quality approved by our client.