-

WhatsAPP: +86 137 1365 3495

-

WeChat: +86 137 1365 3495

-

E-mail: info@ace-mold.com

Injection moulding with high velum high tolerance

Why Choose ACE

● We have a fast response rate. Within moments of receiving an email, we start to work, and quotations are sent within 24 hours.

● We have our own design and development team.

● We have a strong quality control system to ensure the best quality products.

● We offer competitive prices and can beat our competitors.

● We send samples asap, and all samples have gone thru quality inspection.

● We provide OEM/ODM services for all kinds of customers.

● We deliver goods on time and communicate transparently with our customers during shipping.

● We take strong pride in the fact that at least 96% of our customer have been with us since we started.

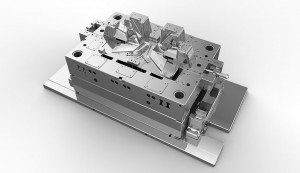

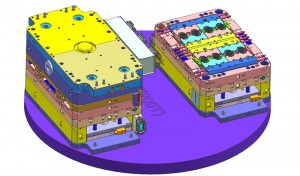

What is Plastic Injection Mould Design?

ACE is equipped with 32 in-house injection moulding machines ranging from 98 to 1200 tons clamping force, which enable us to provide services of mould trial and small volume plastic part production.

The injection moulding department has the capability to operate 24 hours a day to make sure the on-time delivery.

With a good quality control system to monitor all operations performed in a controlled manner and effectively ensures final products' quality.

Meantime, we have a big good relationship partner nearby, which is equipped with machines from 50 to 2000 tons including equipment for two-shot moulding, gas-assisted injection moulding, etc.

This allows us to test a wide range of plastic moulds and make samples for evaluation according to the customer's needs.

We mould all types of thermoplastic or thermosetting material including reinforced and filled plastics.

Be ready to solve customer's most challenging manufacturing problems with advanced moulding technology and rich experience.

Universal plastic materials: PP, PE, ABS, PC, PC+ABS, Nylon+GF, POM, PMMA, PA, PS, and so on.

What Areas is Plastic Injection Moulding Design Best Applied To?

Some of the examples are:

● Automobile parts

● Household appliance

● Medical devices

● Housings for electronics

● Farming tools

● Cosmetics

● Packaging such as lip balm containers, caps, and so on.

● Daily use combs, caps of bottles, wire insulations etc.