Injection mould design is an essential part of any plastic manufacturing process. It is a complex process which requires a great deal of expertise and knowledge in order to produce a successful end product. Injection mould design involves the development of a tool which is used to shape molten plastic into a desired shape. This tool is then used in an injection moulding machine, which heats the plastic and injects it into the mould.

At the core of injection mould design lies the principle of thermodynamics. This principle determines the heat transfer and plastic flow rate, which are essential elements of the injection mould design process. The design of the mould is also determined by the type of plastic being used and the required end product shape. The process of injection mould design involves a number of steps including determining the material, the design of the mould, and the injection process.

Injection mould design must also consider the effect of shrinkage, as plastics shrink as they cool. This must be taken into account when designing the mould, as too much shrinkage can lead to an improperly shaped finished product. The injection mould design must also take into account the injection pressure, which should be set to the optimal level for the plastic being used.

Injection mould design should also include the consideration of the cooling process. This is essential to ensure that the product is cooled evenly and rapidly, while minimizing the risk of warping or other defects. Cooling time must be taken into account when designing the mould, as it will determine the time taken for the plastic to cool and the quality of the finished product.

In conclusion, injection mould design is a complex and time consuming process, but one which is essential for any successful plastic manufacturing process. The right injection mould design can be the difference between success and failure, so it is essential to ensure that the design is done correctly.

What is injection mould design?

Injection mould design is the process of designing a mould which will be used to produce plastic parts through injection moulding. It is a complex process which requires knowledge of the plastic material, the plastic injection moulding process, the end-use application of the parts, and design principles. The design must take into account the type of plastic material, the moulding process, the size and shape of the parts to be produced, and the desired end-use application of the parts.

The injection mould design process begins with the designer creating a model of the part to be produced. This model is then used to create the mould which will be used to produce the parts. The mould must be designed to ensure that the parts produced meet the desired specifications. This includes the shape, size, and material of the parts. The mould must be designed in such a way that it can be produced and used in the injection moulding process.

The injection moulding process

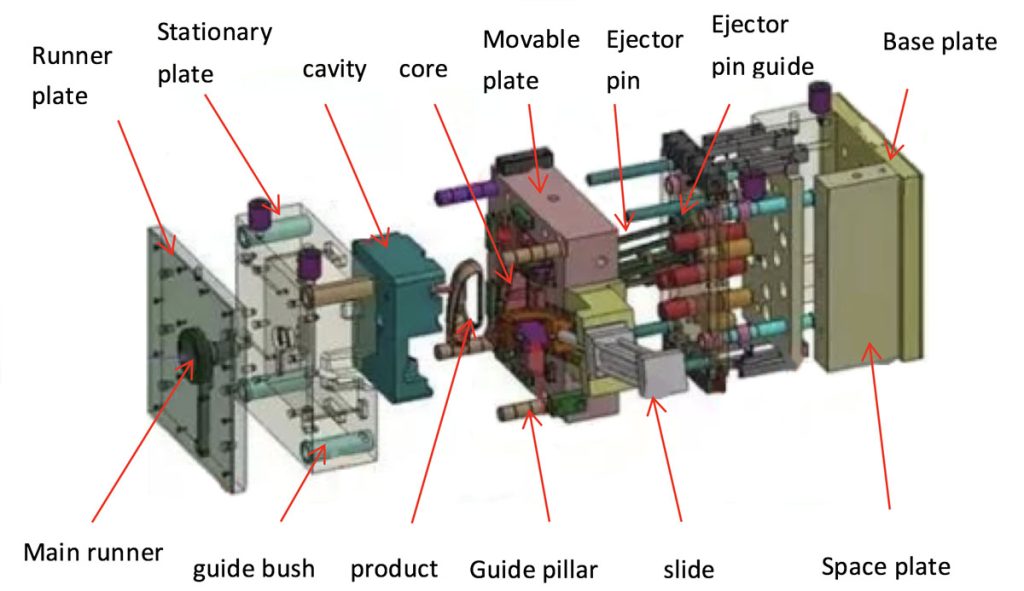

The plastic injection moulding process is a process which uses a mould to produce plastic parts. The process begins by heating plastic pellets in a hopper until they become a molten plastic. This molten plastic is then injected into a mould where it is cooled and solidified. The mould is then opened, and the parts are removed from the mould. The parts are then trimmed and finished to the desired specifications.

Types of injection moulds

There are several types of injection moulds which can be used to produce plastic parts. The type of mould used will depend on the type of parts to be produced and the desired end-use application of the parts. Injection moulds can be made from various materials such as steel, aluminium, and brass. The type of material used will depend on the application and the desired level of strength and durability.

The importance of a good design

A good injection mould design is essential for the success of the plastic injection moulding process. The design of the mould must take into account the type of plastic material, the size and shape of the parts to be produced, and the desired end-use application of the parts. A poorly designed mould can lead to poor quality parts, poor performance, and high production costs. It is important to ensure that the mould is designed to meet the desired specifications and that it is capable of producing high-quality parts.

The injection mould design process

The injection mould design process begins with the designer creating a model of the part to be produced. This model is then used to create the mould which will be used to produce the parts. The mould must be designed to ensure that the parts produced meet the desired specifications. This includes the shape, size, and material of the parts. The mould must be designed in such a way that it can be produced and used in the injection moulding process.

Once the mould has been designed, it must be tested and evaluated to ensure that it meets the desired performance requirements. This testing and evaluation process is often done using computer-aided design (CAD) software. This software allows the designer to simulate the injection moulding process and evaluate the performance of the mould.

Common injection mould design considerations

When designing an injection mould, there are several common considerations which must be taken into account. These include the type of plastic material, the size and shape of the parts to be produced, the desired end-use application of the parts, and the desired performance of the parts. It is important to ensure that the mould is designed to meet the desired specifications and that it is capable of producing high-quality parts.

In addition to these common considerations, designers must also take into account the cost of the mould and the cost of the materials used to produce the mould. It is important to ensure that the cost of the mould does not outweigh the benefits of the mould.

Injection mould design software

Injection mould design software is a computer-aided design (CAD) software which is used to design injection moulds. This software allows the designer to simulate the injection moulding process and evaluate the performance of the mould. This software also allows the designer to create detailed models of the parts to be produced and to test and evaluate the performance of the mould.

Benefits of injection mould design

Injection mould design has many benefits, including improved product quality, increased production efficiency, and reduced costs. An injection mould which is properly designed can produce high-quality parts which meet the desired performance requirements. This can lead to increased customer satisfaction and increased sales.

In addition, an injection mould which is designed properly can also lead to increased production efficiency and reduced costs. An injection mould which is designed to produce parts quickly and efficiently can reduce the amount of time and money spent on production. This can lead to increased profits for the company.

Challenges of injection mould design

Injection mould design is a complex process which requires knowledge and skill to perfect. It is important to ensure that the mould is designed to meet the desired specifications and that it is capable of producing high-quality parts. In addition, designers must also take into account the cost of the mould and the cost of the materials used to produce the mould.

Designers must also be aware of the potential challenges of injection mould design. This includes the potential for warping, shrinkage, and deformation of the parts. In addition, the designer must be aware of the potential for part damage due to improper design and improper handling of the mould.

Conclusion

Injection mould design is a complex process which requires knowledge and skill to perfect. It is an essential part of the plastic injection moulding process, as it will determine the success or failure of the project. In this article, we have looked at what injection mould design is, the injection moulding process, types of injection moulds, the importance of a good design, the injection mould design process, common injection mould design considerations, injection mould design software, benefits of injection mould design, and challenges of injection mould design.

If you are looking to produce plastic parts through injection moulding, it is important to ensure that you have a good understanding of the injection mould design process. By taking the time to understand the process and the potential challenges, you can ensure that you produce high-quality parts which meet the desired specifications.