In the world of plastic product design and manufacturing, having a reliable and skilled plastic die mould manufacturer is crucial for success. One such industry leader is ACE, a renowned manufacturer that specializes in designing and engineering high-quality plastic die moulds. With their expertise and advanced capabilities, ACE empowers businesses to transform their innovative ideas into functional and aesthetically pleasing plastic products. This blog delves into the world of plastic die mould manufacturing, exploring the design and engineering aspects along with the remarkable services offered by ACE.

Designing for Perfection: Unleashing the Power of Plastic Die Moulds

The success of any plastic product lies in its design, and ACE understands this principle well. Their design and engineering blogs provide invaluable insights into plastic product design, engineering principles, CAD software tutorials, and best practices for designing molds. These blogs cater to both beginners and experienced professionals, covering a wide range of topics such as mold flow analysis, parting line design, undercuts, and draft angles. By sharing their knowledge, ACE empowers designers and engineers to master the art of designing plastic products that are not only visually appealing but also functional and manufacturable.

1. Optimizing Designs with Mold Flow Analysis: Premier Plastic Die Mould Manufacturer

One of the key aspects of plastic product design is ensuring optimal functionality and manufacturability. ACE's Customized Plastic Product Design shed light on the significance of mold flow analysis, a powerful tool that simulates the behavior of plastic within the mold during the injection molding process. By analyzing factors such as filling patterns, temperature distribution, and material flow, designers can identify potential issues early in the design phase. This insight allows them to optimize the design, minimize defects, and enhance the overall quality of the final product.

2. Mastering Parting Line Design: Premier Plastic Die Mould Manufacturer

The parting line, where the two halves of the mold separate, is a critical element in plastic product design. ACE's Customized Plastic Product Designs delve into the intricacies of parting line design, emphasizing the importance of precision and accuracy. They discuss various techniques and strategies to create clean and well-defined parting lines, ensuring proper alignment of mold components. Effective parting line design not only enhances the aesthetics of the product but also facilitates seamless production, reducing the risk of defects and improving efficiency.

Engineering Excellence: ACE's Cutting-Edge Capabilities

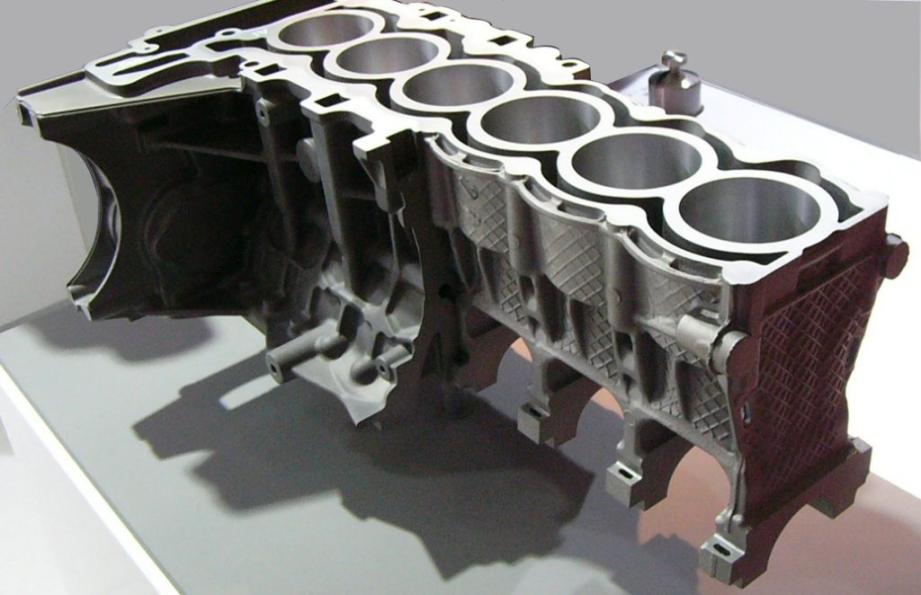

ACE takes great pride in its state-of-the-art manufacturing facilities and cutting-edge capabilities. Their team of highly skilled engineers utilizes advanced software tools and technologies to ensure the highest level of precision and quality in their plastic die moulds. Whether it's a simple and straightforward design or a complex and intricate one, ACE's engineers possess the expertise to tackle any challenge. By leveraging their extensive experience and knowledge, ACE guarantees that their clients receive top-notch products that meet or exceed their expectations.

1. Commitment to Precision and Quality: Premier Plastic Die Mould Manufacturer

Precision and quality are non-negotiable at ACE. Each plastic die mould manufactured undergoes rigorous testing and inspection to ensure it meets the highest standards. ACE's engineers employ meticulous attention to detail, leaving no room for error. This commitment to precision and quality guarantees that ACE's clients receive products that not only meet their specifications but also exceed their expectations. ACE understands that a reliable and durable plastic die mould is essential for the success of their client's manufacturing processes, and they go above and beyond to deliver on this promise.

2. Customization and Flexibility: Premier Plastic Die Mould Manufacturer

Recognizing the diverse needs of its clients, ACE offers a high level of customization and flexibility. Their team of engineers collaborates closely with clients to understand their unique requirements and develop tailored solutions. Whether it's a modification to an existing design or the creation of an entirely new mould, ACE is committed to providing personalized services that align with its client's goals. Their ability to adapt and respond to customer demands sets ACE apart as a trusted partner in the plastic die mould manufacturing industry.

Mold Flow Analysis: Ensuring Optimal Performance and Quality

One crucial aspect of plastic die mould design is mold flow analysis. ACE's design and engineering blogs shed light on the importance of this process and provide insights into its implementation. Mold flow analysis enables designers and engineers to simulate the flow of molten plastic within the mould, identifying potential issues such as air traps, weld lines, and excessive shrinkage. By using advanced simulation software, ACE ensures that its plastic die moulds are optimized for optimal performance, reducing the risk of defects and enhancing the overall quality of the final product.

1. Advanced Manufacturing Facilities: Premier Plastic Die Mould Manufacturer

Underpinning ACE's success is its investment in advanced manufacturing facilities. Equipped with state-of-the-art machinery and tools, ACE ensures that each plastic dies mould they produce is of the highest quality. These cutting-edge facilities enable their engineers to seamlessly translate design concepts into tangible products with precision and efficiency. From computer-aided design (CAD) to computer numerical control (CNC) machining, ACE leverages technology at every stage of the manufacturing process to maintain its reputation for excellence.

2. Cutting-Edge Capabilities: Premier Plastic Die Mould Manufacturer

ACE's team of highly skilled engineers possesses a wealth of experience and expertise, allowing them to tackle even the most complex and intricate design challenges. Their proficiency in utilizing advanced software tools empowers them to optimize the manufacturing process, ensuring accurate and efficient production. By staying abreast of the latest industry trends and technologies, ACE continually enhances its capabilities and maintains a competitive edge. Whether it's a simple and straightforward design or a highly intricate one, ACE rises to the occasion, delivering exceptional results every time.

Parting Line Design: Achieving Seamless Integration

The parting line, where the two halves of the mould meet, plays a critical role in plastic product manufacturing. ACE's design and engineering blogs discuss the intricacies of parting line design and its impact on the final product. They provide guidance on selecting the most suitable parting line location, considering factors such as aesthetics, functionality, and ease of manufacturing. By achieving seamless integration between the two mould halves, ACE ensures that the resulting plastic products have a flawless finish and exhibit exceptional quality.

Beyond the Basics: Tackling Undercuts and Draft Angles

Designing plastic products with undercuts or complex geometries requires specialized expertise, and ACE excels in this domain. Their design and engineering blogs delve into the complexities of handling undercuts and draft angles during the mould design process. ACE's team of experts shares tips and tricks for effectively incorporating undercuts into the design while maintaining manufacturability. Furthermore, they provide insights into selecting appropriate draft angles to facilitate part ejection from the mould, ensuring smooth and efficient production.

Conclusion:

When it comes to plastic die mould manufacturing, ACE stands out as a trusted partner for businesses seeking excellence in design and engineering. Through their informative design and engineering blogs, ACE imparts valuable knowledge and expertise to the industry, enabling professionals to master the art of plastic product design. With their cutting-edge capabilities and commitment to precision, ACE ensures that their plastic die moulds meet the highest standards of quality and performance. Whether it's mold flow analysis, parting line design, or handling undercuts and draft angles, ACE's expertise shines through, ensuring flawless integration and optimal manufacturability. By choosing ACE as your plastic die mould manufacturer, you gain a reliable partner dedicated to transforming your innovative ideas into exceptional plastic products.